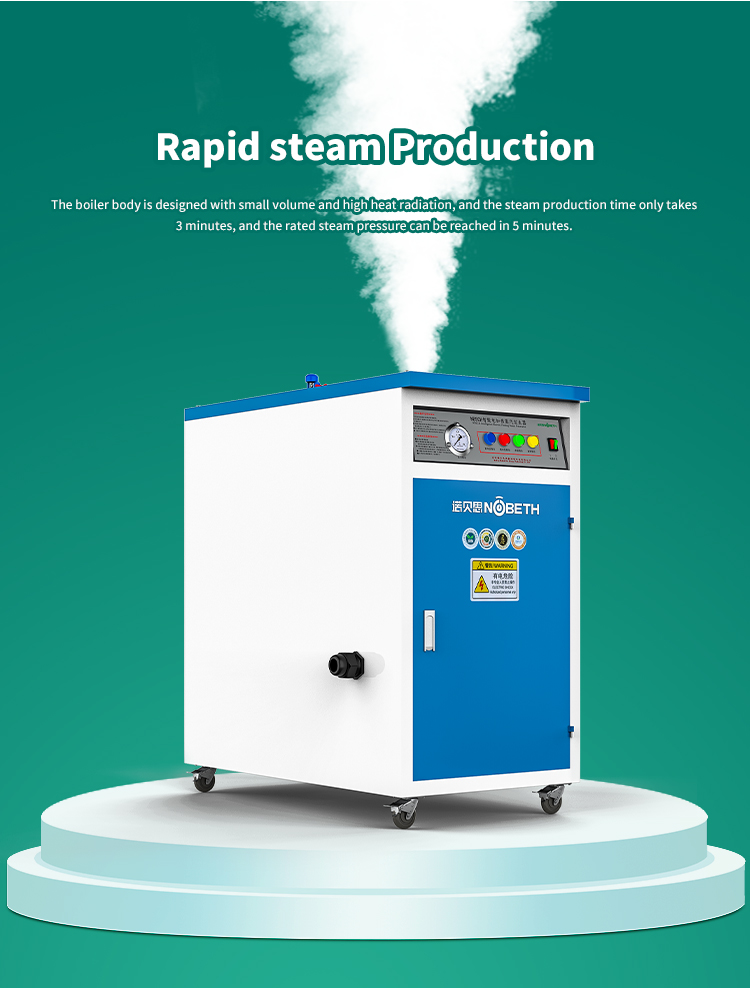

24KW Electric Steam Generator for Iron pressers

2. Classification and characteristics of imported check valves

Check valve:

1. According to the structure, it can be divided into three types: lift check valve, swing check valve and butterfly check valve.

①Lift check valve can be divided into two types: vertical and horizontal.

②Swing check valves are divided into three types: single flap, double flap and multi flap.

③Butterfly check valve is a straight-through type.

The connection forms of the above check valves can be divided into three types: threaded connection, flange connection and welding.

Generally, vertical lift check valves (small diameter) are used on horizontal pipelines with a nominal diameter of 50mm. The straight-through lift check valve can be installed on both horizontal and vertical pipelines. The bottom valve is generally only installed on the vertical pipeline of the pump inlet, and the medium flows from bottom to top. Lift check valves are used where quick closing is required.

The swing check valve can be made into a very high working pressure, the PN can reach 42MPa, and the DN can also be made very large, the largest can reach more than 2000mm. Depending on the material of the shell and the seal, it can be applied to any working medium and any working temperature range. The medium is water, steam, gas, corrosive medium, oil, food, medicine, etc. The medium working temperature range is between -196~800℃. The applicable occasion of butterfly check valve is low pressure and large diameter.

3. The selection of the steam check valve should meet the following requirements

1. The pressure should generally be able to withstand PN16 or more

2. The material is generally cast steel and stainless steel, or chrome-molybdenum steel. It is not suitable to use cast iron or brass. You can choose imported steam cast steel check valves and imported steam stainless steel check valves.

3. The temperature resistance must be at least 180 degrees. Generally, soft-sealed check valves cannot be used. Imported steam swing check valves or imported steam lift check valves can be selected, and stainless steel hard seals are used.

4. The connection method generally adopts flange connection

5. The structural form generally adopts swing type or lift type.

Products categories

-

E-mail

-

Phone

-

WhatsApp

-

Top