60KW Electric heating steam generators generally use indirect methods

1. The application of electric heating steam generator in slaughtering and scalding chicken feathers with boiling water is similar. The cold water is heated with high-temperature steam, and the hot water at an appropriate temperature is helpful for the shedding of pig and chicken feathers, and avoids plucking and tearing of the skin.

2. During the electroplating process, it is necessary to use the high-temperature steam generated by the electric heating steam generator to heat the water temperature to about 90 degrees. The specific process is: electrolysis for 15 minutes, then coloring in a hot water pool (stay for about 45 minutes), and then wash.

3. The dishwasher is equipped with an electric heating steam generator, which mainly uses steam to burn hot water. Clean the dishes first, then remove Du. The cleaning water temperature is about 50 degrees, and the water temperature is about 85 degrees.

Electric heating steam generators generally use indirect methods. It can only output steam, pass it into the water, and heat the water.

To sum up, using an electric heating steam generator to boil water is one of its application methods, and many industries operate in this way, so it has no effect on water.

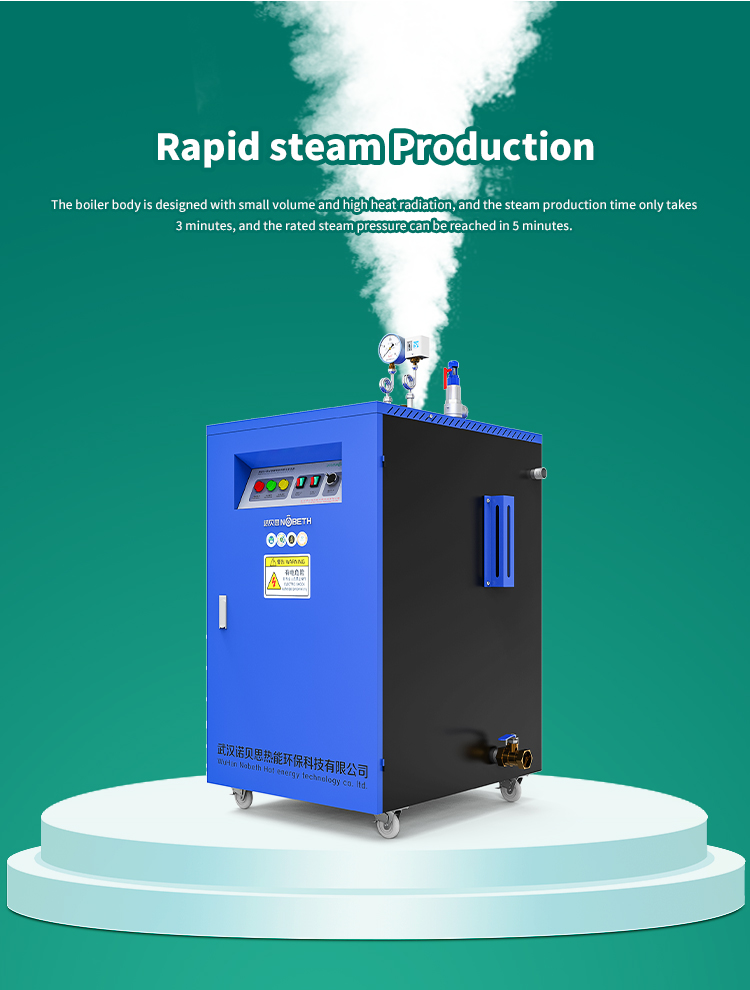

Nobles electric heating steam generator has the following advantages:

1. The shell of the product is made of thickened steel plate and special painting process, which is exquisite and durable, and has a very good protection effect on the internal system. You can also customize the color according to your needs.

2. The interior adopts the design of water and electricity separation, which is scientific and reasonable, and the functional modules can be operated independently to enhance the stability during operation and prolong the service life of the product.

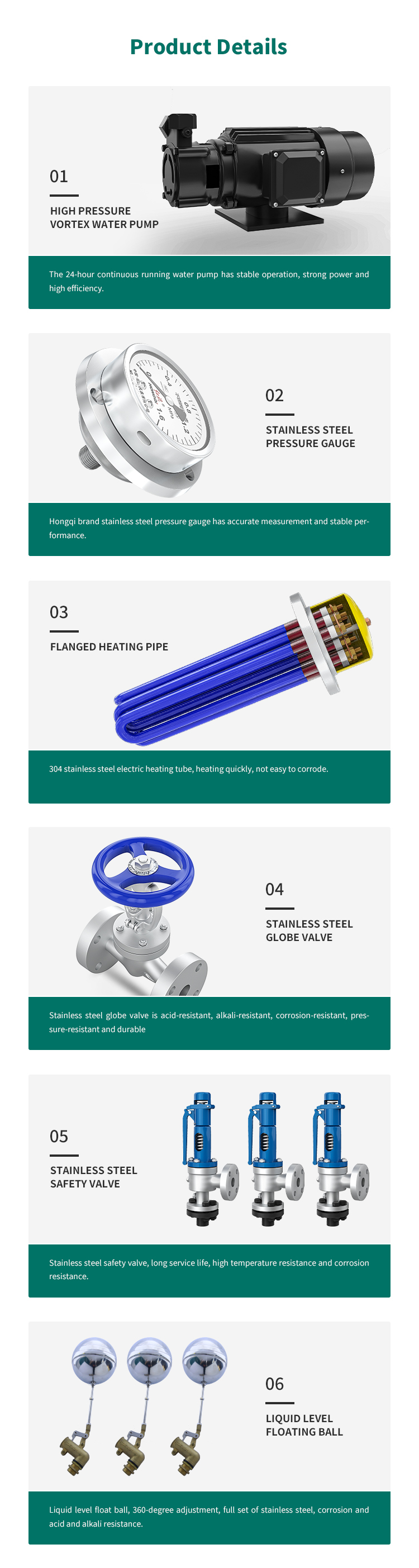

3. The protection system is safe and reliable, with multiple safety alarm control mechanisms for pressure, temperature and water level, which can be automatically monitored and guaranteed. It is also equipped with high-safety and high-quality safety valves to comprehensively protect production safety.

4. The internal electronic control system can be operated with one button, the temperature and pressure can be controlled, the operation is convenient and fast, saving a lot of time and labor costs, and improving production efficiency.

5. Microcomputer automatic control system, independent operation platform and human-computer interactive terminal operation interface can be developed, 485 communication interface is reserved, and with 5G Internet of Things communication technology, local and remote dual control can be realized.

6. The power can be adjusted in multiple gears according to the needs, and different gears can be adjusted for different production needs, saving production costs.

7. The bottom is equipped with universal wheels with brakes, which can move freely, and can also customize the skid-mounted design to save installation space.

It can be widely used in industries such as medical, pharmaceutical, biological, chemical, food processing and other thermal energy special supporting equipment, especially for constant temperature evaporation.

Products categories

-

E-mail

-

Phone

-

WhatsApp

-

Top