NBS GH 48KW Fully Automatic Electric Heating Steam Generator used for Steel Steam Oxidation Treatment Process

In a self-designed steam treatment furnace, the steam treatment process of commonly used ordinary carbon 45# steel was studied, and the scratch method, X-ray, SEM and other methods were used to study the bonding strength, thickness, composition and composition of the steam-treated surface oxide film. Related characteristics.

The results show that the optimal steam treatment process is heating at 570°C, holding for 3 hours, and dripping water at 0.175ml/min. The bonding force with the film is basically stronger than the traditional blackening process. However, the density of the steam-treated oxide film is worse than that of the blackened one, and the critical load decreases as the holding time increases under the same heating temperature and dripping amount.

What is steam treatment? Which parts are suitable for processing? The so-called steam treatment is a process in which steel parts are heated in saturated steam at 540 to 560°C to form a uniform, dense, blue magnetic Fe3O4 film with a thickness of about 2 to 5 meters on the surface of the steel. It has good resistance to Corrosion and anti-rust effect, while also improving the service life of the tool.

From the perspective of steam treatment, since its working temperature is above 500°C, its cost is high and special steam treatment equipment is required. Nobis steam generator can customize high-temperature and high-pressure steam generators to generate high-temperature saturated steam, which is Steam treatment of steel parts can achieve great results!

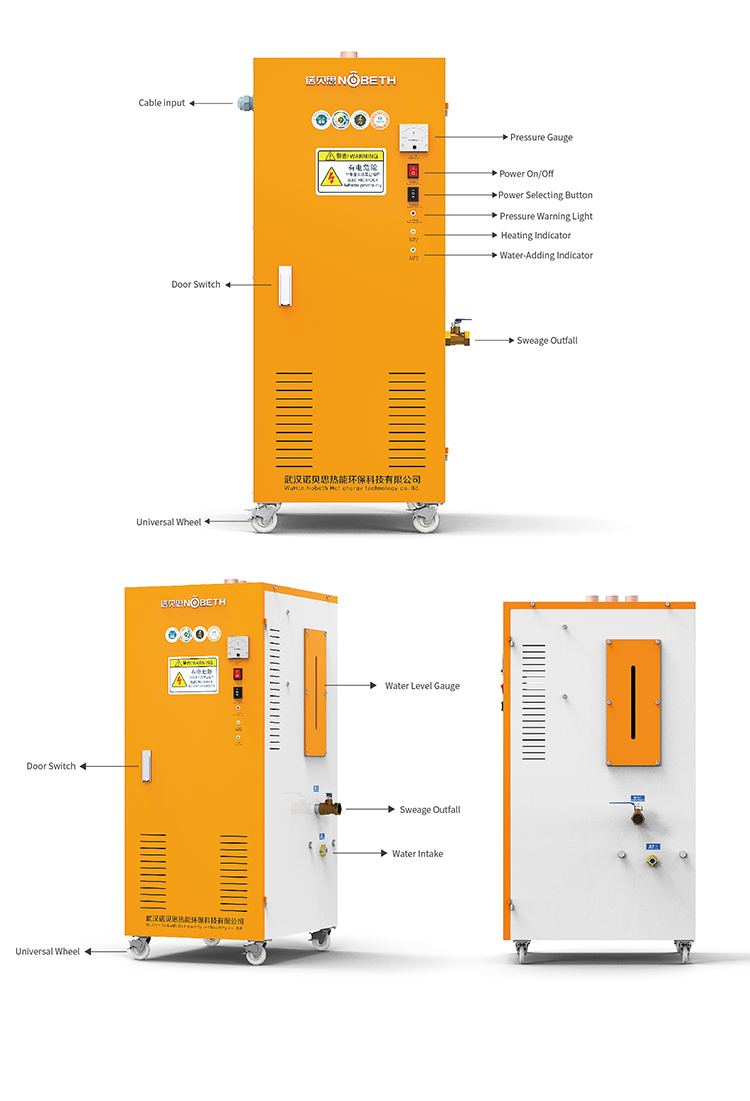

High temperature and high pressure steam generator

Nobeth high temperature and high pressure steam generator has a wide range of functions. Because of its high temperature characteristics, it is widely used in various production and processing industries:

① Steam treatment is most suitable for high-speed steel and high-alloy tool steel tools. Since the tempering temperature of high-speed steel tools matches it, the steam treatment process is also a tempering process. At the same time, a Fe3O4 film is formed, which can improve corrosion resistance and The service life is 20% to 30%. It can prevent the generation of oxide scale (Fe2O3·FeO) in the steam furnace, ensuring the accuracy of the tool. Carbon steel and general low-alloy steel will cause a decrease in hardness at this temperature, so they are not suitable for use.

② Suitable for surface treatment of silicon steel sheets, which can obtain a large and uniform resistance value, saving valuable insulating paint.

③Suitable for anti-rust and hole filling treatment of powder metallurgy to improve its hardness and compressive strength.

④Suitable for surface treatment of some non-alloy workpieces to improve their rust resistance.

⑤ Suitable for surface treatment of screws and nuts made of carbon steel to enhance the appearance and anti-rust ability.

Nobeth high-temperature and high-pressure steam generators are manufactured in accordance with national pressure vessel standards. They are equipped with high-pressure water pumps, which can replenish water when there is high pressure in the container. They are high-pressure explosion-proof and scale-free designs. The power can be infinitely adjusted. They are easy to use, safe and efficient!

Products categories

-

E-mail

-

Phone

-

WhatsApp

-

Top