With the development of science and technology and the country’s continuous emphasis on environmental protection, electric steam generators are becoming more and more popular in the market, and many companies will be more inclined to purchase electric steam generators for production and life. But what parts does a fully automatic electric heating steam generator consist of? Only by fully understanding the products can we better use and master these devices. Next, Nobeth will take you to understand the components of a fully automatic electric heating steam generator.

Electric heating steam generator is mainly composed of water supply system, automatic control system, furnace and heating system and safety protection system.

1. The water supply system is the throat of the fully automatic steam generator, continuously supplying users with dry steam. When the water source enters the water tank, turn on the power switch, driven by the automatic control signal, the high-temperature resistant solenoid valve opens, the water pump works, and is injected into the furnace through the one-way valve. When the solenoid valve or one-way valve is blocked or damaged and the water supply reaches a certain pressure, the water will overflow back to the water tank through the overpressure valve to protect the water pump. When the water tank is cut off or there is residual air in the water pump pipeline, only air and no water will enter. As long as the exhaust valve is quickly exhausted, when water spurts out, close the exhaust valve, and the water pump can work normally. The most important component in the water supply system is the water pump. Most of them use multi-stage vortex pumps with higher pressure and larger flow rate. A small number of them use diaphragm pumps or vane pumps.

2. The liquid level controller is the central nervous system of the generator automatic control system and is divided into two categories: electronic and mechanical. The electronic liquid level controller controls the liquid level (that is, the height difference of the water level) through three electrode probes of different heights, thereby controlling the water supply of the water pump and the heating time of the furnace electric heating system. The working pressure is stable and the application range is relatively wide. . The mechanical liquid level controller adopts stainless steel float type, which is suitable for generators with large furnace volumes. The working pressure is not stable, but it is easy to disassemble, clean, maintain and repair.

3. The furnace body is generally made of special seamless steel tubes for boilers and is in a slender upright shape. Most of the electric heating tubes used in electric heating systems are composed of one or more bent stainless steel electric heating tubes, and their surface load is generally around 20 watts/cm2. Since the generator has high pressure and temperature during normal operation, the safety protection system can make it safe, reliable and efficient in long-term operation. Generally, safety valves, one-way valves, and exhaust valves made of high-strength copper alloy are used to implement three-level protection. Some products also add a water level glass tube protection device to increase the user’s sense of security.

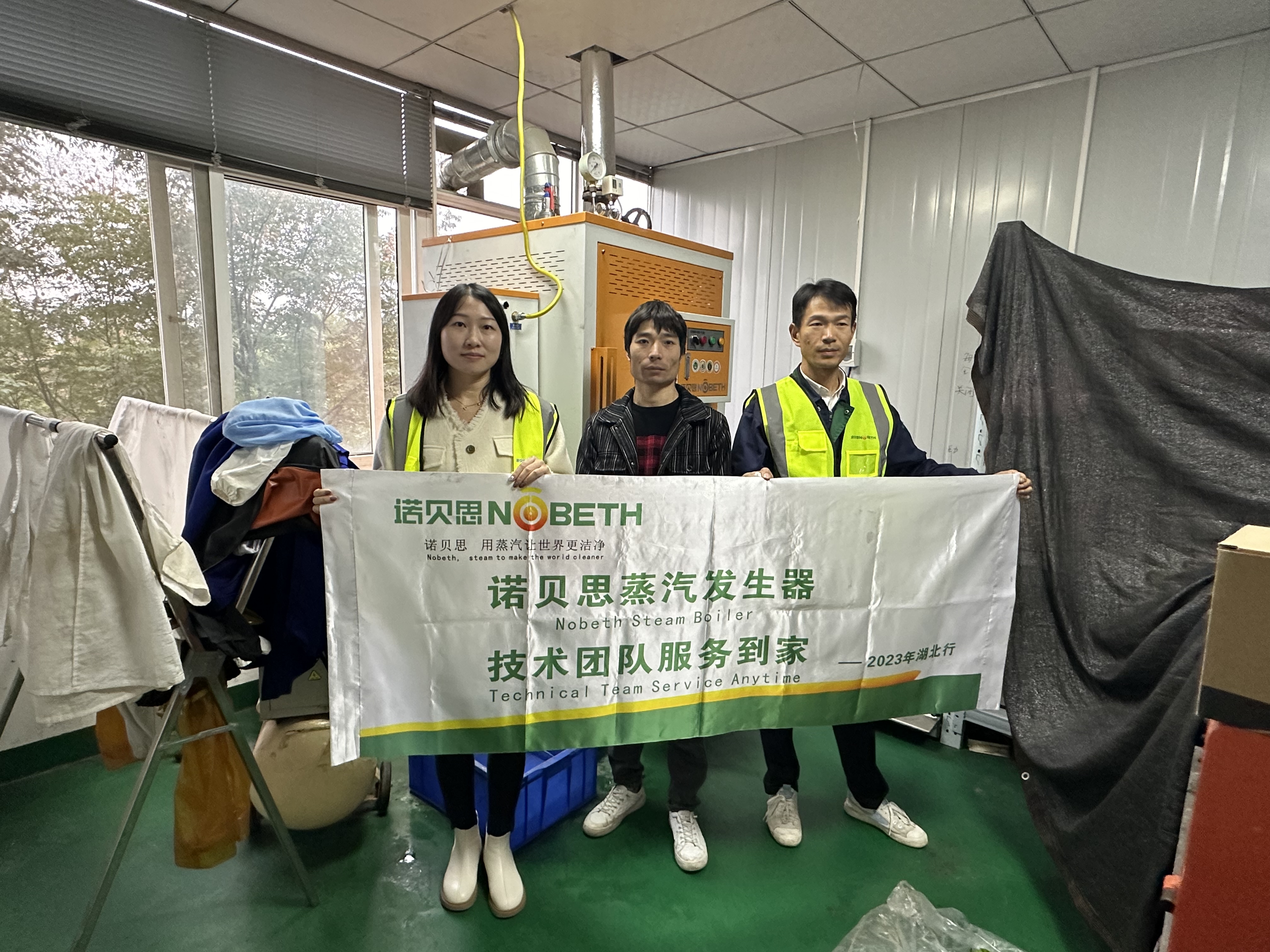

The above is the analysis of the components of the fully automatic steam generator analyzed by Wuhan Nobeth. If you have any questions, you can continue to consult our customer service staff.

Post time: Nov-30-2023