NOBETH GH 18KW Fully Automatic Electric Steam Generator is used in The Dyeing and Finishing Process

The four processes in the dyeing and finishing industry: refining, dyeing, printing and finishing are all inseparable from steam, and electric steam generators, as heat source equipment for generating steam, are naturally indispensable. Compared with the traditional method of purchasing a steam generator, silk printing and dyeing uses the steam generated by a special electric steam generator for garment ironing, which can effectively reduce the waste of steam heat sources.

Generally, fiber materials need to be washed and dried repeatedly after chemical treatment, which consumes a lot of steam heat energy. In the process, harmful substances will be produced to pollute the air and water. Therefore, efforts must be made to improve steam utilization and reduce pollution during printing and dyeing. In the printing and dyeing process, heat sources are generally bought in the form of steam.However, almost all the equipment used cannot directly use the high-pressure steam that has just entered the factory. The steam bought at a high price needs to be cooled down for use. This will lead to insufficient steam on the machine, and eventually form a problem. The contradiction between high-temperature and high-pressure steam that cannot be used directly and insufficient steam input into the equipment has resulted in a waste of steam. But now that there is an electric steam generator for clothing ironing, the situation is very different.

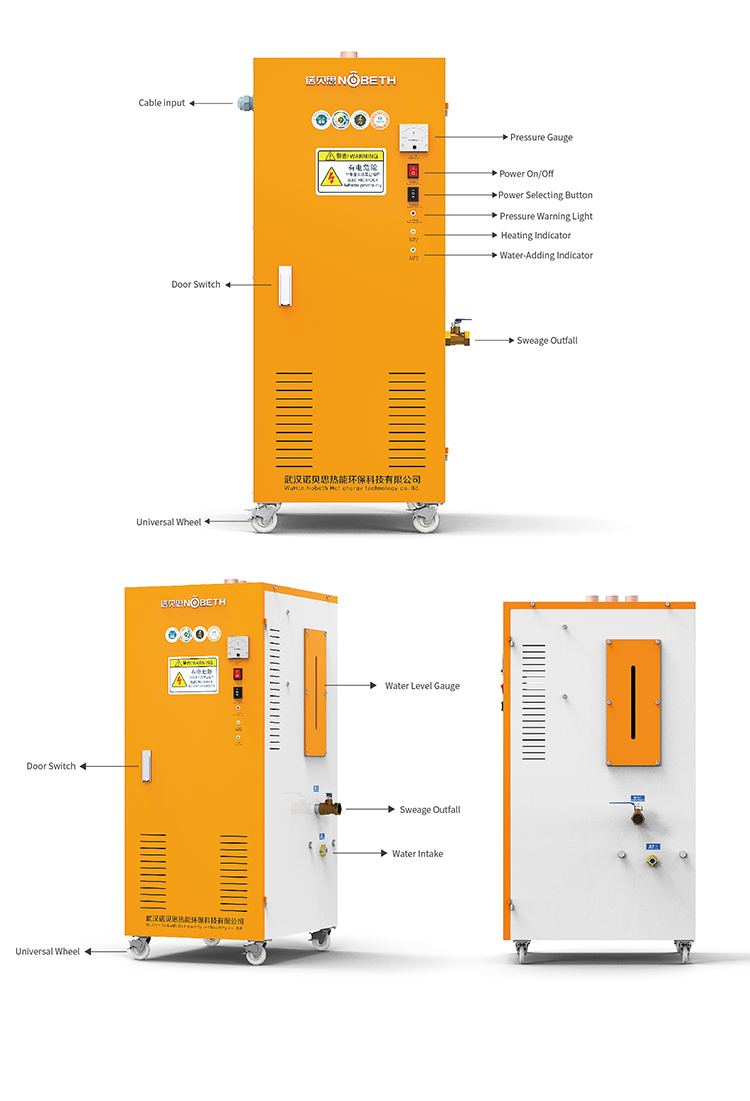

The garment ironing steam generator has high thermal efficiency, fast gas production, and the generated steam is pure and hygienic. The most important thing is that the steam generator is also equipped with an exhaust gas recovery device, which greatly improves the steam utilization rate and replaces the heating method of purchased steam. The Chengdian steam generator generates steam for silk fabric printing and dyeing. The imported pressure controller can adjust the steam pressure according to production needs to avoid the above-mentioned contradiction of wasting steam. One-button fully automatic operation will not increase labor consumption. Greatly improve the economic benefits of garment factories.

High-temperature sterilization steam generator helps dry cleaners clean autumn and winter clothes

One autumn rain and another cold. In the blink of an eye, the hot summer has become a thing of the past. With the advent of autumn, we also put on warm and heavy autumn and winter clothes. Unlike light summer clothes, it is more difficult for individuals to wash autumn and winter clothes, such as down jackets, woolen coats, etc. Therefore, most people choose to clean and maintain autumn and winter clothes at dry cleaners. So, how do dry cleaners clean autumn and winter clothes quickly and well? This has to mention our high temperature sterilization steam generator.

The difference between dry cleaning and water cleaning is that dry cleaning does not use water to wash away the dirt on the clothes, but uses organic chemical solvents to clean various stains on the clothes, so the clothes that are dry cleaned will not get wet with water. , and there will be no shrinkage or deformation of clothes caused by dehydration required for washing. However, if you want to clean the chemical solvents on heavy autumn and winter clothing, you must use a high-temperature sterilization steam generator.

In order to prevent the clothes from being eaten by insects or deteriorating after dry cleaning, many regular dry cleaning shops will disinfect and sterilize the clothes. Ultraviolet disinfection and sterilization are very harmful to the human body, and some clothes are made of materials that cannot withstand it. Therefore, in order to ensure that the quality of customers’ clothes is not affected, many dry cleaners choose to use high-temperature sterilization steam generators to sterilize down jackets.

The high-temperature sterilization steam generator has high thermal efficiency, and the steam generated is pure and hygienic. It can easily strip away chemical solvents remaining on clothes, providing a strong guarantee for people’s clothing health. Moreover, the steam generator only has a small part of the function of disinfecting and sterilizing dry-cleaned clothes. The high-temperature sterilizing steam generator can also be used with an iron to iron the clothes to ensure they are clean and stylish. Therefore, it is favored by the dry cleaning industry.

Products categories

-

E-mail

-

Phone

-

WhatsApp

-

Top