90kw Electric Steam Generator for Food Industry

Steam generator reaction after using well water and river water:

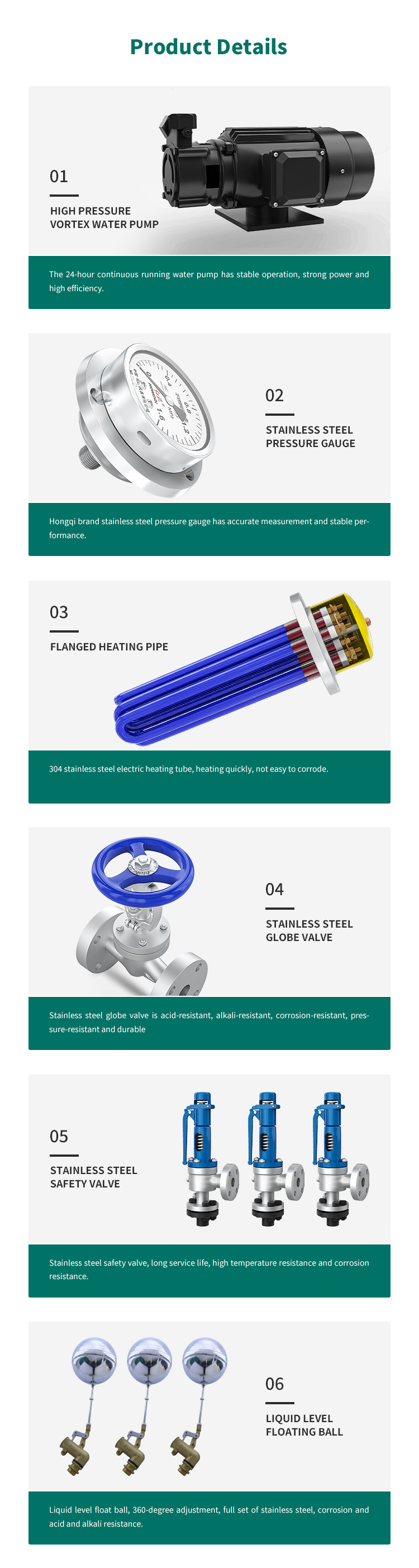

1. If there is too much mud in the liquid level controller, it will cause operation failure, failure to work, and burning of the heating tube.

2. Too much dirt on the outside of the electric heating tube will greatly reduce the service life of the electric heating tube.

3. Too much mud outside the heating tube will prolong the heating time and increase power consumption.

Pay attention to timely sewage discharge when using the steam generator, twice a day, the sewage discharge pressure is 0.15map. Only in this way can the pipes be prevented from clogging, the sewage pipes can be connected correctly, and burns can be avoided, and the correct use of the steam generator will greatly improve the service life of the machine and save electricity costs at the same time.

The thermal conductivity of scale is a few thousandths of that of copper and one hundredth of that of steel. After fouling, if you want to reach the boiler water temperature without scaling, the temperature of the heating surface will rise. For example, the wall temperature of a 10-ton boiler is 280 degrees Celsius. When the silicate scale is 1mm, it should reach the same temperature as the furnace water, and the wall temperature should be raised to 680 degrees Celsius. At this time, the strength of the furnace steel plate will decrease, resulting in an explosion, and the increase in temperature will cause material stress failure and increase energy consumption.

The purpose of boiler water treatment is clear. It is necessary to eliminate the harm of scaling to the boiler, save energy consumption, prolong the service life of the boiler, and improve the integrity rate of the boiler. The main factor of scaling is calcium and magnesium ions dissolved in water. Especially in steam boilers, the concentration factor of boiler water is usually 20-30 times. Any water treatment method is dangerous if it does not remove calcium and magnesium ions. According to the water supply requirements of the steam boiler, the method of removing calcium and magnesium ions outside the furnace must be used, that is, the method of removing calcium and magnesium ions outside the furnace. Demineralized water is used as boiler feed water. The steam generator uses ion resin softened water as the feed water for the heater, which can effectively reduce the impact of scaling on the heater.

Products categories

-

E-mail

-

Phone

-

WhatsApp

-

Top