Steam generator is one of the main energy equipment used in production and is a type of special equipment. Steam generators are used in many aspects of our lives and are closely related to our clothing, food, housing, transportation and other aspects. In order to standardize the design and use of steam generators and make their operation safer and more reliable, relevant departments have formulated many relevant regulations so that steam generators can better benefit our lives.

1. Application fields of steam generators

Clothes: clothing ironing, dry cleaning machines, dryers, washing machines, dehydrators, ironing machines, irons and other equipment are used in conjunction with them.

Food: Provide supporting equipment for drinking boiled water, cooking food, producing rice noodles, boiling soy milk, tofu machines, steaming rice boxes, sterilization tanks, packaging machines, sleeve labeling machines, coating equipment, sealing machines, tableware cleaning and other equipment.

Accommodation: room heating, central heating, floor heating, community central heating, auxiliary air conditioning (heat pump) heating, hot water supply with solar energy, (hotels, dormitories, schools, mixing stations) hot water supply, (bridges, railways) concrete maintenance , (leisure beauty club) sauna bathing, wood processing, etc.

Industry: cleaning of cars, trains and other vehicles, road maintenance, painting industry, etc.

2. Specifications related to steam generators

Steam generators play an important role in our industrial production, and the safety of their production is closely related to daily life. Therefore, when producing equipment, we should strictly control production, comply with relevant regulations, and produce safe and efficient related equipment.

On October 29, 2020, the “Boiler Safety Technical Regulations” (TSG11-2020) (hereinafter referred to as the “Boiler Regulations”) was approved and promulgated by the State Administration for Market Regulation.

This regulation combines the “Boiler Safety Technical Supervision Regulations” (TSG G0001-2012), “Boiler Design Document Appraisal Management Rules” (TSG G1001-2004), “Fuel (Gas) Burner Safety Technical Rules” (TSG ZB001-2008), “Fuel (Gas) Burner Type Test Rules” (TSG ZB002-2008), “Boiler Chemical Cleaning Rules” (TSG G5003-2008), “Boiler Water (Medium) Treatment Supervision and Management Rules” (TSG G5001-2010), Nine boiler-related safety technical specifications including “Boiler Water (Medium) Quality Treatment Inspection Rules” (TSG G5002-2010), “Boiler Supervision and Inspection Rules” (TSGG7001-2015), “Boiler Periodic Inspection Rules” (TSG G7002-2015) Integrate to form comprehensive technical specifications for boilers.

In terms of materials, according to the requirements of Chapter 2, Article 2 of the “Boil Regulations”: (1) The steel materials for the pressure components of the boiler and the load-bearing components welded to the pressure components should be killed steel; (2) The steel materials for the pressure components of the boiler (cast The room temperature Charpy impact absorbed energy (KV2) shall not be less than 27J (except steel parts); (3) The longitudinal room temperature post-fracture elongation (A) of the steel used for boiler pressure components (except steel castings) shall not be less than 18%.

In terms of design, Article 1 of Chapter 3 of the “Boil Regulations” states that the design of boilers should meet the requirements of safety, energy saving and environmental protection. Boiler manufacturing units are responsible for the design quality of the boiler products they manufacture. When designing the boiler and its system, the system should be optimized based on energy efficiency and air pollutant emission requirements, and relevant technical parameters such as the initial emission concentration of air pollutants should be provided to the boiler user.

In terms of manufacturing, Article 1 of Chapter 4 of the “Boil Regulations” states: (1) Boiler manufacturing units are responsible for the safety, energy saving, environmental protection performance and manufacturing quality of boiler products leaving the factory, and are not allowed to manufacture boiler products that have been eliminated by the state; (2) Boiler manufacturers Harmful defects should not be produced after material cutting or bevel processing, and pressure components are formed. Cold forming should avoid cold work hardening that causes brittle fracture or cracking. Hot forming should avoid harmful defects caused by too high or too low forming temperature. ; (3) Repair welding of cast iron parts used in pressure-bearing parts is not allowed; (4) For pipelines within the scope of power station boilers, temperature and pressure reduction devices, flow meters (casings), factory prefabricated pipe sections and other component combinations should be Manufacturing supervision and inspection shall be carried out in accordance with the requirements of boiler components or pressure piping component combinations; pipe fittings shall be subject to manufacturing supervision and inspection in accordance with the relevant requirements of boiler components or type testing shall be carried out in accordance with the relevant requirements of pressure piping components; steel pipes, valves, compensators and other pressure piping components , type testing should be carried out in accordance with the relevant requirements for pressure piping components.

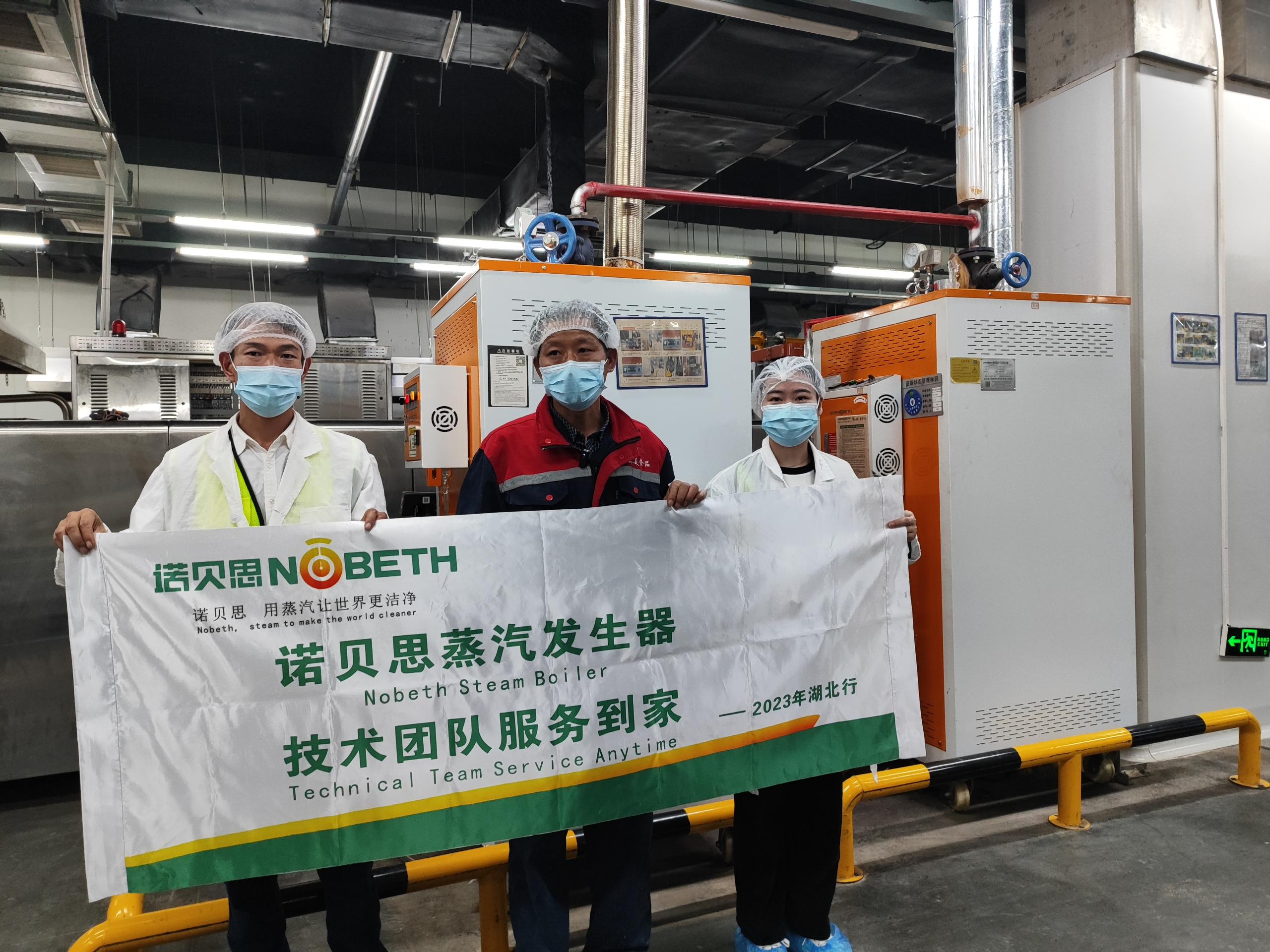

3. Nobeth steam generator

Wuhan Nobeth Thermal Environmental Protection Technology Co., Ltd., located in the hinterland of Central China and the thoroughfare of nine provinces, has 23 years of experience in steam generator production and can provide users with a complete set of steam boiler solutions including selection, manufacturing, transportation, and installation. When designing and manufacturing related steam equipment, Nobeth strictly implements relevant national regulations, absorbs advanced experience at home and abroad, continuously carries out technological innovation and reform, and produces advanced equipment that meets the requirements of the times.

Nobeth Steam Generator strictly controls all production links, follows national regulations, and takes energy conservation, environmental protection, high efficiency, safety, and inspection-free as its five core principles. It has independently developed fully automatic electric heating steam generators and fully automatic gas steam generators. , fully automatic fuel steam generators, environmentally friendly biomass steam generators, explosion-proof steam generators, superheated steam generators, high-pressure steam generators and more than 200 single products in more than ten series, their quality and quality can stand The test of time and market.

Post time: Nov-16-2023