Organic fertilizer refers to a type of fertilizer with active microorganisms, a large number of elements argon, phosphorus and potassium, and rich organic matter, which is composed of specific functional microorganisms and organic materials that are mainly derived from animal and plant residues and have been harmlessly treated and decomposed.

Bio-organic fertilizer has many advantages such as no pollution, no pollution, long-lasting fertilizer effect, strong seedlings and disease resistance, improved soil, increased yield, and improved quality. The crops applied with bio-organic fertilizers generally show strong plant growth, increased leaf greenness, increased photosynthetic efficiency, strong after-effects of fertilizers, and the crops are not easy to pull seedlings, prolonging the harvest period.

At present, most organic fertilizers are produced by harmless treatment methods, mainly collecting and concentrating raw materials first, and then dehydrating to make the moisture content reach 20% to 30%. Then transport the dehydrated raw materials to a special steam disinfection room. The temperature of the steam disinfection room should not be too high, generally 80-100 degrees Celsius. If the temperature is too high, nutrients will be decomposed and lost. The fertilizer is continuously running in the disinfection room, and after 20-30 minutes of disinfection, all insect eggs, weed seeds and harmful bacteria are killed. Then the sterilized raw materials are mixed with necessary natural minerals, such as phosphate rock powder, dolomite and mica powder, etc., granulated, and then dried to become an organic fertilizer. The technological process is as follows: raw material concentration – dehydration – deodorization – formula mixing – granulation – drying – sieving – packaging – storage. In short, through the harmless treatment of organic fertilizers, the purpose of degrading organic pollutants and biological pollution can be achieved.

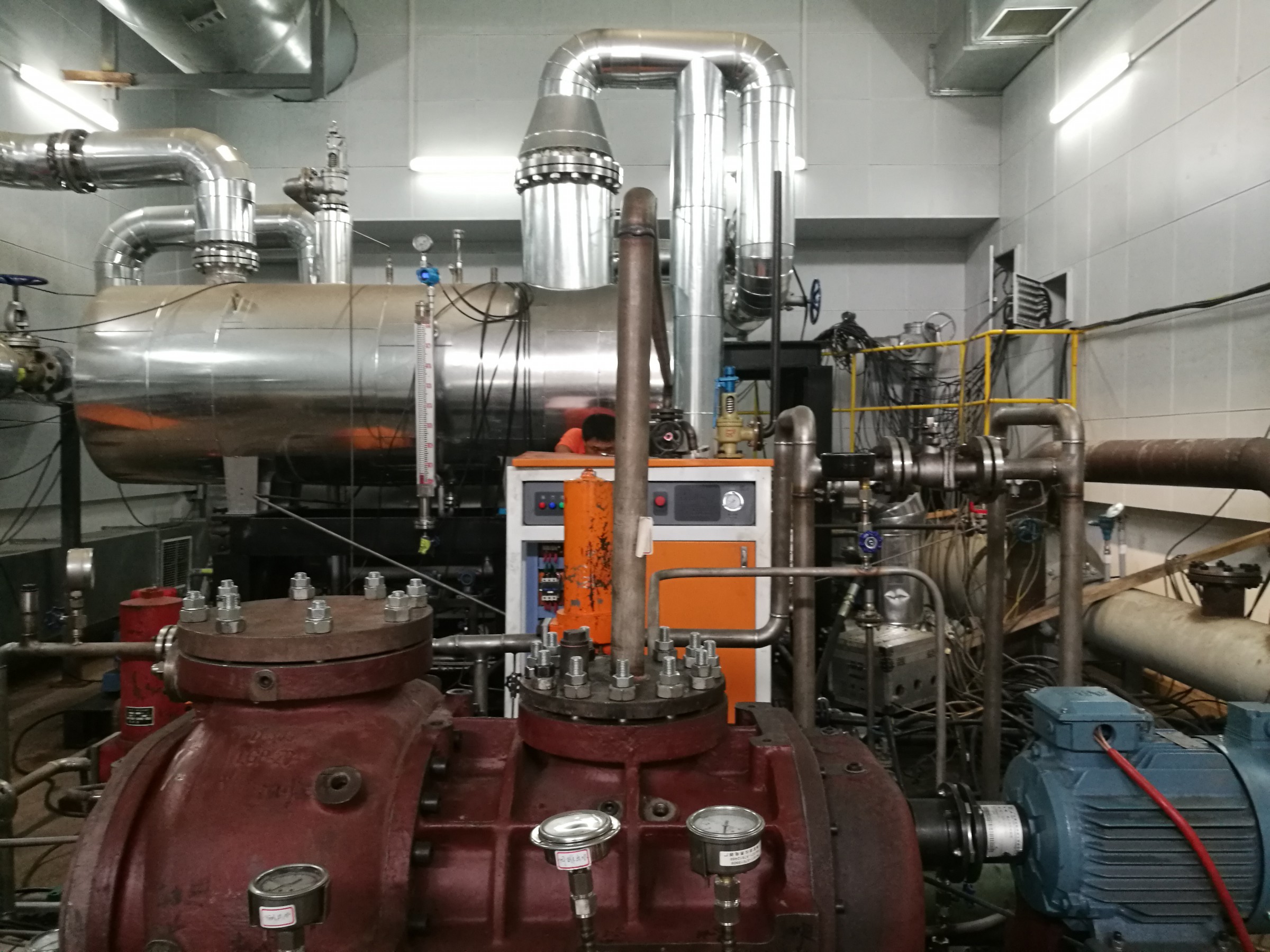

The steam generator is mainly used for disinfection and drying in the process of organic fertilizer production. It generates steam through the fully premixed surface combustion technology. The steam temperature is as high as 180 degrees Celsius, which can meet the temperature requirements of organic fertilizers. The steam generator can provide steam 24 hours a day, which greatly improves the efficiency of enterprise production.

Post time: Sep-07-2023