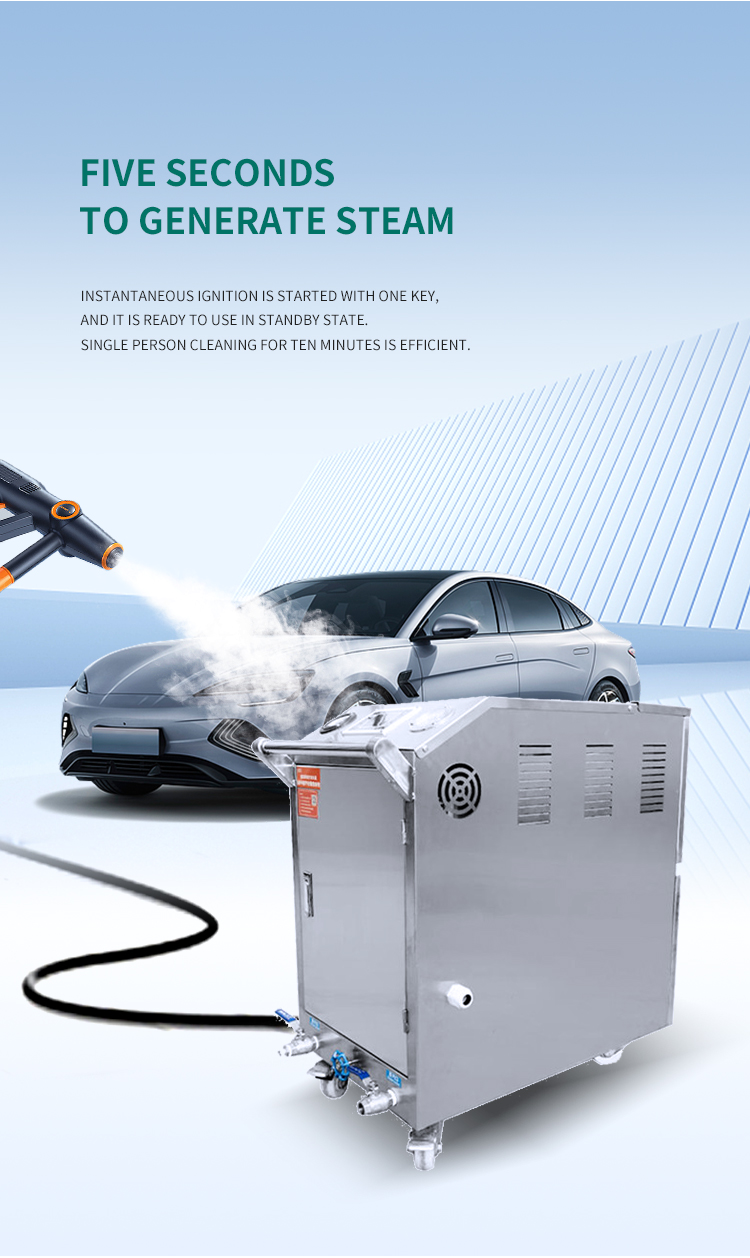

NOBETH 12KW Electric Steam Washer used for Cleaning and Processing of Mechanical Parts

In fact, there are many methods for cleaning mechanical parts. The most frequently used ones are ultrasonic cleaning machine cleaning and high-temperature cleaning steam generator cleaning. However, usually after an ultrasonic cleaning machine cleans parts, some white marks will appear on the surface of the workpiece after natural air drying. Therefore, it needs to be rinsed to thoroughly clean it. However, using a high-temperature cleaning steam generator to clean the workpiece does not require So troublesome.

White marks will appear on mechanical parts after cleaning with ultrasonic cleaning agents. This is because a cleaning agent to remove oil stains is added to the cleaning tank. After cleaning, some liquid containing cleaning agents will remain on the surface of the mechanical parts. After the flame retardant inspiration, White marks will appear, just like washing clothes with washing powder. If the rinse is not clean, there will be white marks on the clothes after drying. This is caused by not rinsing the washing powder cleanly. At the same time, The white traces on the parts will only appear if they are not rinsed. Therefore, you must rinse when using ultrasonic cleaning to ensure the cleanliness of the workpiece. When using a high-temperature cleaning steam generator to clean mechanical parts, there is no need to use cleaning. agent, which eliminates the subsequent rinsing process.

Many people may be curious. It is difficult to remove oil stains on mechanical parts. Can it really be cleaned without using detergent? The answer is yes. High-temperature steam can quickly penetrate into every angle of mechanical parts and wipe away the stubborn oil stains attached to them. Therefore, it can be cleaned without adding detergent. Most importantly, the Nobeth steam generator can also adjust the temperature and pressure according to the cleaning needs of mechanical parts. This is why mechanical processing plants choose high-temperature cleaning steam generators for cleaning. The real reason for cleaning mechanical parts is gone.

Products categories

-

E-mail

-

Phone

-

WhatsApp

-

Top