NOBETH BH 360KW Fully Automatic Electric Steam Generator is used in the Brewing Process

Winemaking is a high-alcohol liquor extracted from fermented winemaking raw materials through one or more distillation processes. The principle of making distilled wine is to vaporize the alcohol based on its physical properties to extract high-purity liquor. Based on this, the role of steam generators in its production process is becoming more and more important.

Through the use of a 1-ton steam generator and a 1-ton boiler in the brewing process, it was found that the comprehensive energy saving of the steam generator is between 10% and 30%. Moreover, steam generators have great advantages in terms of labor costs, annual inspection fees, cold start/steam output time, startup gas consumption, and volume. According to actual operation calculations, compared with boilers, steam generators save approximately 100,000 yuan per year.

The steam generator not only has huge advantages in energy saving, but also can continuously and stably output steam according to the temperature required by the distillation process, and the steam temperature is close to 200 degrees Celsius, so it can ensure the high temperature requirements of the distillation process. All this is due to the fully premixed surface combustion technology of the through-flow chamber used in the steam generator. Gas and air are fully mixed before combustion without preheating. After entering the combustion rod, they can be quickly and fully burned to meet the requirements of rapid temperature rise; Moreover, the gas steam generator adopts automatic program control. After setting parameters according to needs, the gas steam generator operates automatically without the need for special personnel to operate safely.

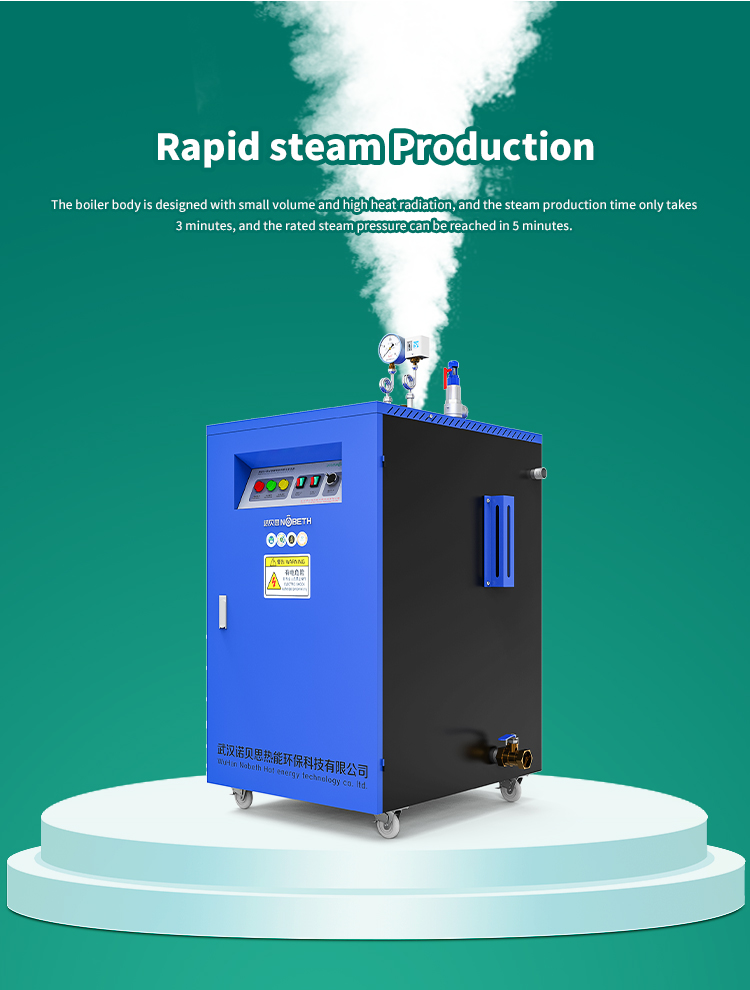

The brewing steam generator produced by Nobeth is specially designed for brewing. It is an innovative product developed using patented technology. The water tank fire tube of this product is made of high-quality imported 304 stainless steel. The control system is designed and customized by the largest manufacturer in China. It has a fully automatic ignition method. It has high thermal efficiency, high energy saving, simple style, easy operation, good combustion performance and significant energy saving effect. It has the characteristics of intelligent control, environmental protection and safety, fast steam production, large evaporation capacity, low noise, and easy installation and use. Nobeth brewing steam generators have been widely used in various industries and are favored by customers.

Products categories

-

E-mail

-

Phone

-

WhatsApp

-

Top