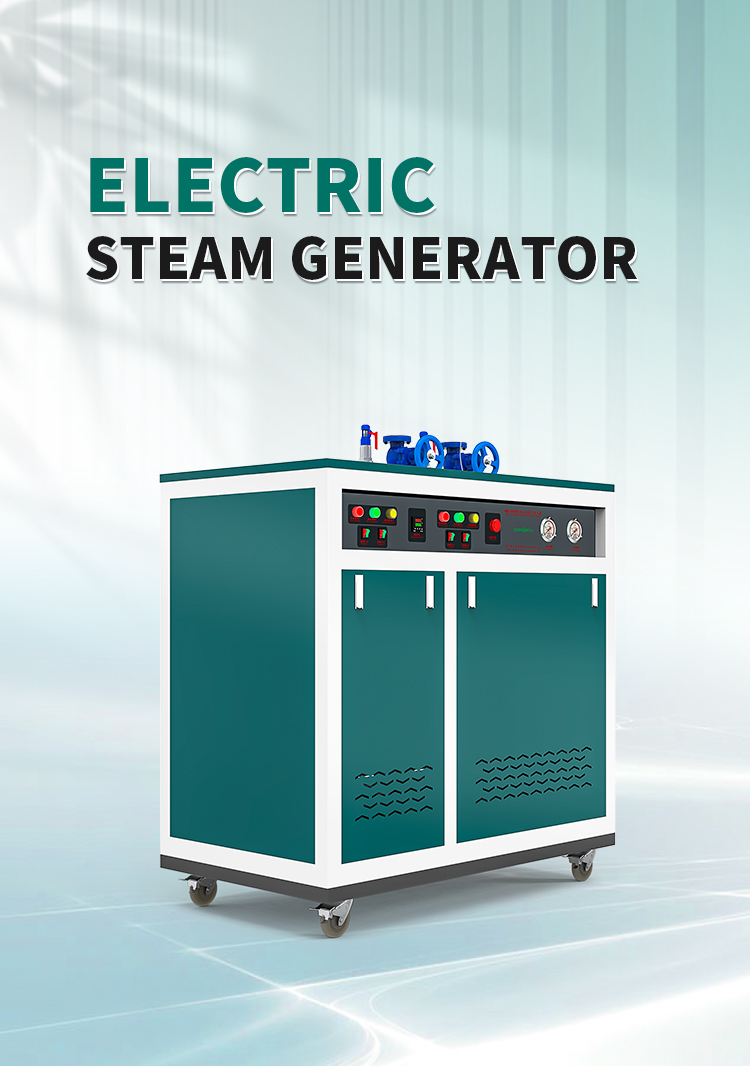

108KW Electric Steam Generator for Concrete Maintenance

One-click fully automatic. The user only needs to set the temperature and prepare a suitable power supply at the beginning, and there will be a steady stream of steam.

Concrete steam curing can be divided into four stages: static stop, heating, constant temperature and cooling. The steam curing of concrete should meet the following four requirements:

1. During the static stop period, the ambient temperature should be kept not lower than 5°C, and the temperature can only be raised after the completion of pouring and the final setting of the concrete for 4 to 6 hours.

2. The heating rate should not exceed 10°C/h.

3. During the constant temperature period, the internal temperature of the concrete should not exceed 60°C, and the oversized concrete should not exceed 65°C. The constant temperature curing time should be determined through tests based on the demoulding strength requirements of the components, the concrete mix ratio, and environmental conditions.

4. The cooling rate should not be greater than 10°C/h.

The temperature and pressure of the Nobeth steam generator can be adjusted freely, and it can continuously and stably output according to the set temperature, which can better stimulate the mellow aroma of soybean products. After the temperature reaches the set value, the Nobeth steam generator will automatically become a constant temperature mode, which saves a considerable amount of fuel costs in long-term operation, which is beyond the reach of ordinary steam generators.

Nobeth steam generator has developed a microcomputer control system with high control precision. It is equipped with a steam drainage system to prevent the bean dregs in the soy milk from forming; put tap water or pure water into the water tank before use, and put the water into When it is full, it can be continuously heated and used for more than 30 minutes; the water tank has a built-in safety valve, and when the pressure exceeds the set pressure of the safety valve, it will automatically open the safety valve drainage function; safety protection device: automatically cut off when the boiler is short of water (water shortage protection device) power supply.

Products categories

-

E-mail

-

Phone

-

WhatsApp

-

Top