90kg Industrial steam Generator

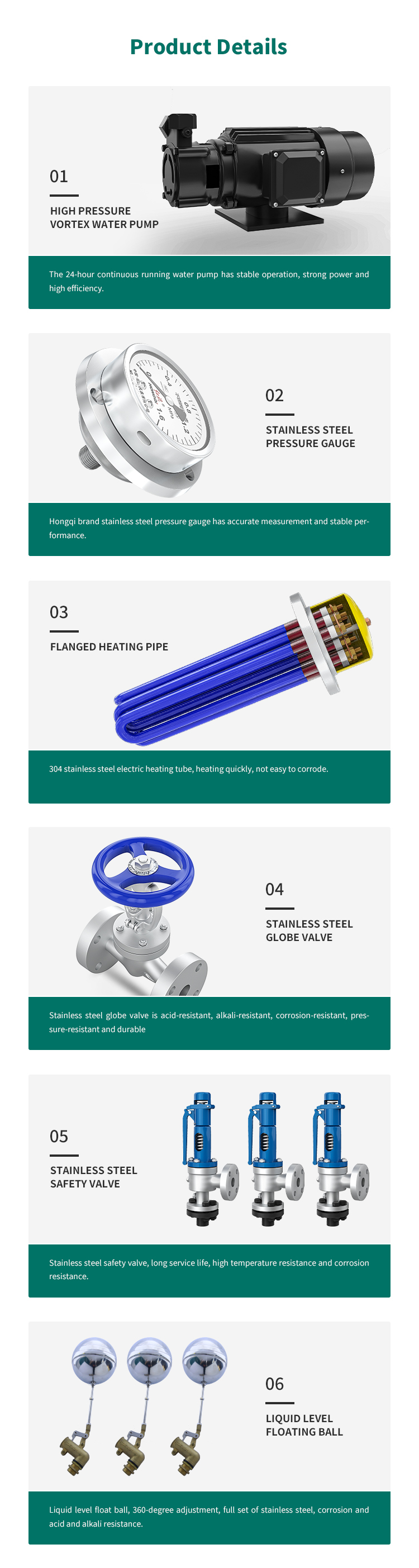

NBS-AH Series is the first choice for packing Industry. Inspection-free products,multiple styles are aviliable.Probe version,float valve version,universal wheels version. The steam generator is made of high quality thickened plate with special spray painting.It is attractive and durable.The stainless steel water tank extends the service life.Separate cabinet is easy for maintenance.The high pressure pump can extract exhaust heat. Temperature,pressure,safety valve ensures tripple security.Four powers switchable and adjustable temperature and pressure.

| Model | NBS-AH-108 | NBS-AH-150 | NBS-AH-216 | NBS-AH-360 | NBS-AH-720 | NBS-AH-1080 |

| Power (kw) |

108 | 150 | 216 | 360 | 720 | 1080 |

| Rated pressure (MPA) |

0.7 | 0.7 | 0.7 | 0.7 | 0.7 | 0.7 |

| Rated steam capacity (kg/h) |

150 | 208 | 300 | 500 | 1000 | 1500 |

| Saturated steam temperature (℃) |

171 | 171 | 171 | 171 | 171 | 171 |

| Envelop dimensions (mm) |

1100*700*1390 | 1100*700*1390 | 1100*700*1390 | 1500*750*2700 | 1950*990*3380 | 1950*990*3380 |

| Power supply voltage(V) | 380 | 220/380 | 220/380 | 380 | 380 | 380 |

| Fuel | electricity | electricity | electricity | electricity | electricity | electricity |

| Dia of inlet pipe | DN8 | DN8 | DN8 | DN8 | DN8 | DN8 |

| Dia of inlet steam pipe | DN15 | DN15 | DN15 | DN15 | DN15 | DN15 |

| Dia of safty valve | DN15 | DN15 | DN15 | DN15 | DN15 | DN15 |

| Dia of blow pipe | DN8 | DN8 | DN8 | DN8 | DN8 | DN8 |

| Weight (kg) | 420 | 420 | 420 | 550 | 650 | 650 |

Write your message here and send it to us

Products categories

-

E-mail

-

Phone

-

WhatsApp

-

Top