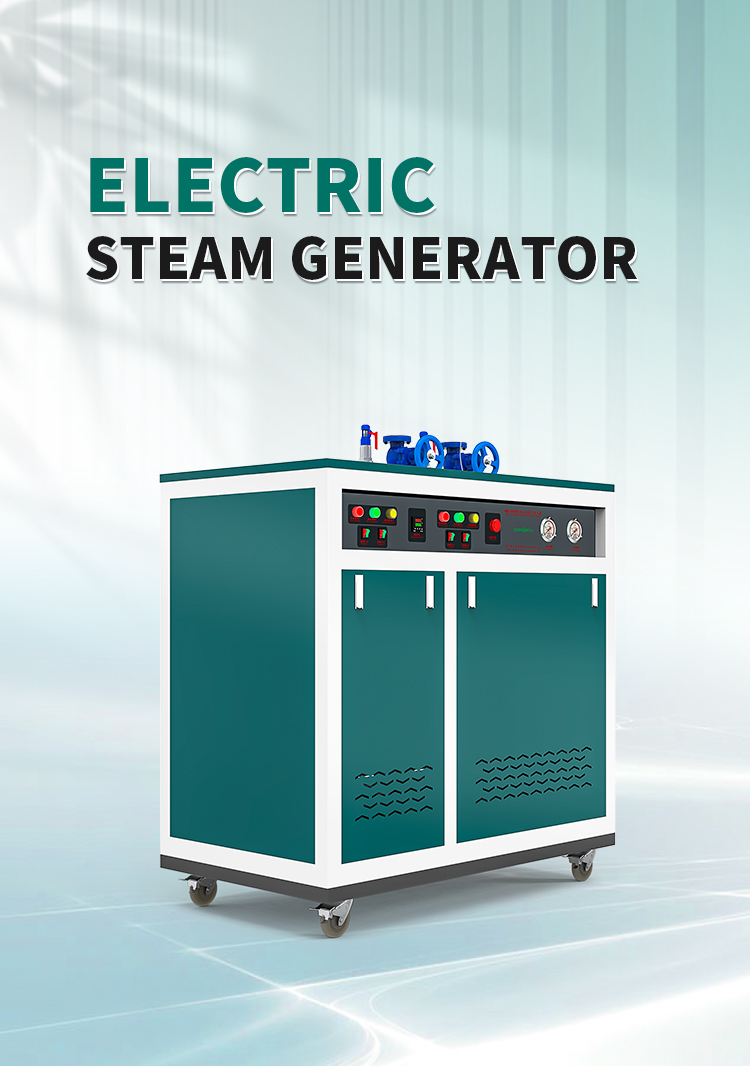

180kw Electric Steam Generator for Wine Distillation

For grain cooking, the demand for steam should be large and uniform, so as to ensure that the grain is heated evenly and cooked. There is no pressure requirement for steam. Temperature is directly proportional to pressure. The higher the temperature, the greater the steam pressure and the faster the grain will steam. The focus here is on the steam channel movement ensuring that the grain is heated evenly. Steam equipment can be selected according to the maximum amount of steamed grain required for production and the steam demand of the size of the steamer. The steam pressure of 0.4MPA~0.5MPA is completely sufficient.

The degree of saccharification directly affects the alcohol yield. The adjustment of saccharification temperature and saccharification time is mainly based on malt quality, auxiliary material ratio, material-water ratio, wort composition, etc. The situation is different, and there is no generalization. set mode. Experienced winemakers will set a relatively constant saccharification and fermentation temperature based on experience. For example, the temperature of the fermentation room is 20-30 degrees, and the temperature of the fermentation material does not exceed 36 degrees. Under low temperature conditions in winter, the effect of precise temperature control and constant temperature moisturizing can be achieved through steam equipment.

Distilled wine is the original wine that is brewed. Utilizing the difference between the boiling point of alcohol (78.5°C) and the boiling point of water (100°C), the original fermentation broth is heated between the two boiling points to extract high-concentration alcohol and aroma. element. Distillation principle and process: The vaporization point of alcohol is 78.5°C. The original wine is heated to 78.5°C and maintained at this temperature to obtain vaporized alcohol. After the vaporized alcohol enters the pipeline and cools, it becomes liquid alcohol. However, during the heating process, substances such as moisture or impure steam in the raw materials will also be mixed into the alcohol, resulting in different quality wines. Most famous wines use different processes such as multiple distillation or wine heart extraction to obtain wines with high purity and low impurity content.

The process of cooking, saccharification and distillation is not difficult to understand. The distillation of wine requires steam. The steam is pure and hygienic, ensuring the quality of the wine. The steam is controllable, the temperature is adjustable, and the control is precise, ensuring convenient cooking and distillation operations. From the perspective of production and operation, steam energy consumption equipment and energy saving are the topics that users are most concerned about.

The new steam generator subverts the traditional principle of steam output. The pipe enters water and outputs steam. It can be used immediately after starting up, with high thermal efficiency. There is no water, the steam is clean and hygienic, and the repeated boiling of dirty water is eliminated, and the scale problem is also eliminated, and the service life of the equipment is extended. The energy-saving effect is 50% of electric steam equipment and 30% of gas steam equipment. High efficiency, energy saving and environmental protection!

Products categories

-

E-mail

-

Phone

-

WhatsApp

-

Top