48KW Electric Steam Generator for Line Disinfection

Sources of Pipeline Contamination

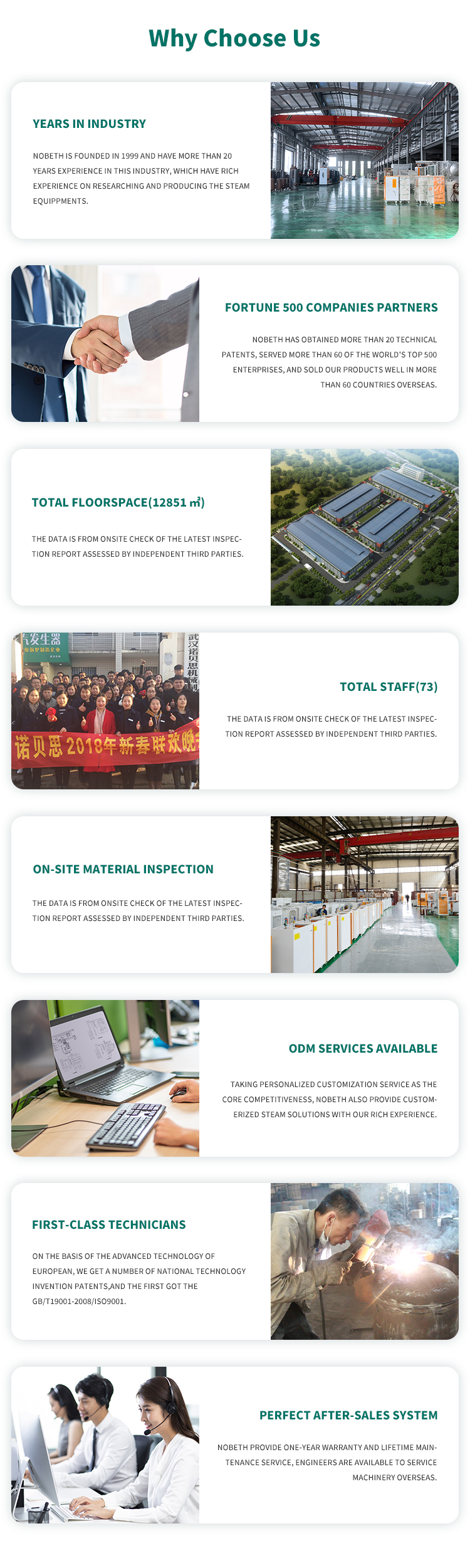

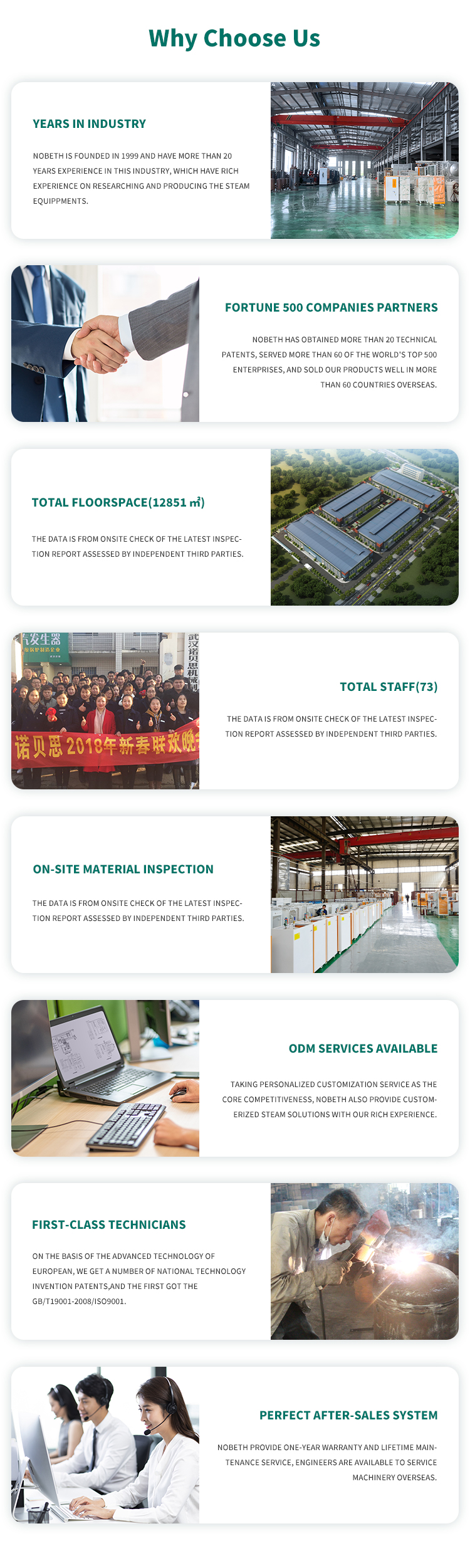

As part of the direct contact with food, the inner wall of the pipe has always been difficult to detect its hygienic condition. In fact, the inner wall of the pipeline is hidden and damp, and it is easy to breed microorganisms and germs. When the product solution passes through the pipeline, the risk of infection with mold, yeast and other pathogenic bacteria is extremely high. Once the food is contaminated, it is easy to spoil and deteriorate, endangering human health. Therefore, it is extremely important to do a good job in the disinfection and sterilization of the inner wall of the pipeline.

Compared with the disinfection of other production links, the inner wall of the pipeline is often more difficult. This is because after the pipeline has been used for a long time, the microbial bacteria in the pipeline can easily develop resistance to the disinfectant, which makes the microorganisms multiply and grow unscrupulously on the inner wall of the pipeline and “build a nest” to form a layer of biofilm. Biofilm is composed of microorganisms mixed with some impurities and adheres to the inner wall of the pipe for a long time. Over time, a layer of strong sticky film is formed. It is difficult to remove by traditional cleaning methods. In addition, the water pipe has small diameter, many bends, and slow water flow. After the food passes through the pipeline, the bacteria will overflow the biofilm with the water flow, causing secondary pollution of the food.

Disinfection and sterilization method

1. Chemical agent sterilization method: Chemical agent sterilization method is the most widely used sterilization method. First of all, the dirt of the equipment is removed by CIP cleaning. The “dirt” is exactly the nutrients required for the growth of bacteria on the food contact surface, including fat, carbohydrates, proteins and minerals. Most manufacturers usually clean the pipeline Use caustic soda; then use some special chemical cleaning agents to destroy the propagules of microorganisms, thereby reducing the number of other microorganisms. This method is cumbersome to operate, and the cleaning is not thorough, and the chemical cleaning agent is also prone to residues, causing secondary pollution.

2. Steam sterilization method: Steam sterilization is to link the high-temperature sterilization steam generated by the steam generator to the pipeline equipment that needs to be sterilized, and destroy the breeding conditions of the bacteria group through high temperature, so as to achieve the purpose of sterilization at one time. The steam sterilization method is easy to operate, with one-button operation of the steam generator, adjustable temperature, fast steam production, large steam volume, relatively thorough sterilization, and no pollution residue. It is one of the most popular sterilization methods at present.

Nobeth sterilization special steam generator adopts 304 stainless steel liner, with high steam purity and large steam volume, it is one of your indispensable partners in pipeline sterilization work.

Products categories

-

E-mail

-

Phone

-

WhatsApp

-

Top